Links machine is a professional liquid and beverage packaging machine supplier in china. Insist on innovation, provide top-grade products and excellent service is our guarantee to win the market.

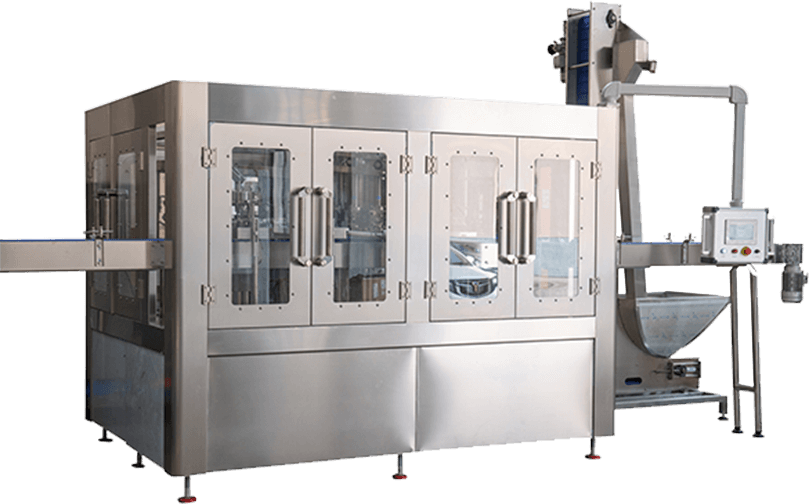

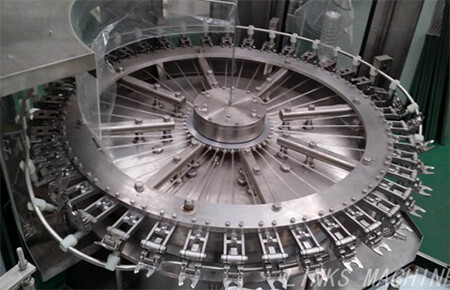

Our packaging equipment covers the field of beverages, alcohol, dairy, condiments and personal care products. According to the customer's packaging design and factory layout, we will provide you most professional packaging solutions, including bottle design, beverage formula, water treatment, pre-treatment, blowing system, filling system and packaging system.

In the future, we will keep up with the global beverage packaging industry trends and provides newset filling packaging solutions. To build the ultimate beverage factory with the newest industrial intelligence technology.