©2019-2020 Zhangjiagang Links Machinery Co.,Ltd. All rights reserved.Site Map Privacy Policy

- Mail Us: info@links-machine.com

- Call now: +86 158 5164 6970

LINKS semi-automatic stretch bottle blowing machine with microcomputer controlling system. PET bottle blowing machine controls various technical parameter needed more accurately and more steadily. Only one person without special training operates PET bottle machine more easily and more safely.

2000BPH Semi-auto 4-Cavity Bottle Blow Molding Machine(0.1L-2L)

1). Stable performance with advanced PLC.

2). Automatic preform conveyer to save human cost.

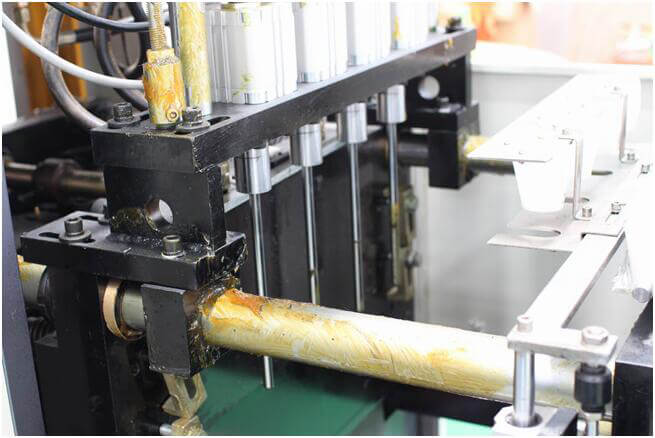

3). Preform self-rotation and infrared pre-heater revolution assure the even distribution of heat, which improve the bottle shaping rate, increase the production.

4). High adjusting performance to enable preheat the preforms perfectly by adjust the voltage control area in the PLC, which could adjust the temperature of the infrared lights in the pre-heater, and keep the proper temperature and humidity invariable.

5). High safeties with security automatic-locking device in each mechanical action, which will make the production into a perfect safe environment, in case of the breakdown in certain procedure.

6). Introduce the FESTO air cylinder to avoid contamination and noise.

7). Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

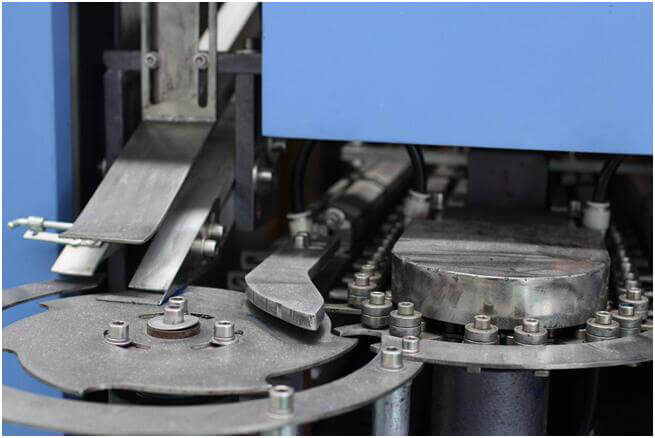

8). Strong clamping force with high pressure and double crank links to lock the mould.

9). Two ways of operating: automatic and manual.

10). Safe\reliable and unique design of the position of valve to make the pneumatic diagram in the machine easier to understand.

11). Low cost\high efficiency\easy operation and maintenance etc, profited from the fully automatic technological process.

12). Ideal cooling system make the finished bottles without any flaws.

13). Easy for you to install\test and start up.

14). Low rejection rate: less than 0.2 percent.

| Model | LKSA-4 |

| Clamping force | 300KN |

| Clamping stroke | 350mm |

| Max. stretching stroke | 380mm |

| Number of cavities | 4-Cavity |

| Theoretical output | 1800-2000BPH |

| Max. mold thickness | 190mm |

| Electrical system | |

| Voltage standard | 380v/3PH/50Hz or special order |

| Total power (full loaded) | 18KW |

| Container | |

| Max. container volume | 2.5L |

| Neck diameter range | 15-45mm |

| Max. container diameter | 110mm |

| Max. container height | 370mm |

| Auxiliary system | |

| High air compressor | >1.2m3/3.0Mpax2 (0.5L) |

| Dimension & weight (LxWxH) | |

| Blow molding machine | 1.9x0.88x1.8m |

| Pre-heater | 1.9x0.66x1.6m |

| Net weight | 1.3T |

| Item | Name | Brand name |

| 1 | Cylinder for stretching unit | FESTO |

| 2 | Pneumatic par for clamping unit | FESTO |

| 3 | Sealing cylinder | FESTO |

| 4 | Blowing Solenoid Valves | FESTO |

| 5 | Sealing solenoid valve | FESTO |

| 6 | Clamping Solenoid valve | AIRTAC |

| 7 | Stretching Solenoid valve | FESTO |

| 8 | PLC controller | TIANJING |

| 9 | Breaker | DELIXI |

| 10 | AC contactor | DELIXI |

| 11 | inverter | DELTA |