©2019-2020 Zhangjiagang Links Machinery Co.,Ltd. All rights reserved.Site Map Privacy Policy

- Mail Us: info@links-machine.com

- Call now: +86 158 5164 6970

Automatic bottle blowing molding machine is suitable for producing PET plastic contains and bottles in all shapes. It is widely used to produce water bottles, carbonated bottles, oil bottles and etc.

•Stable performance with advanced PLC, and operate the whole machine with human-machine interface touch screen, which make the operation and adjustment easy.

•Heating temperature and blowing time etc technology parameters are corresponding set according to customer’s different preform and bottle shape.

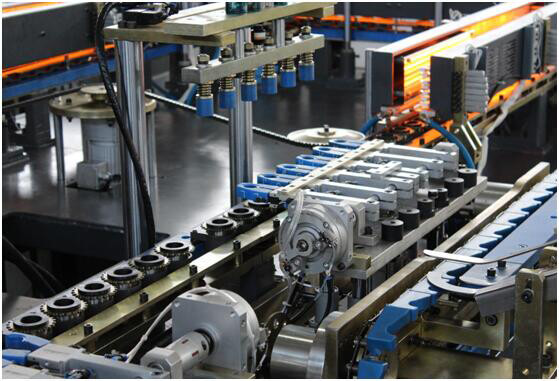

•Equip with automatic preform unscrambler and preform elevator.

•Low cost, high efficiency, easy maintenance, with automatic technological process.

6000BPH 0.1-2L 6-Cavity Automatic Bottle Blow Moulding Machine

| Features | Advantage |

| Linear construction | Stable reliable production with high speed |

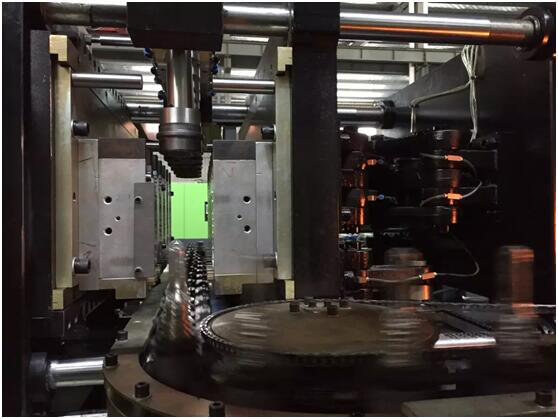

| Blow mould | Light weight, fast speed production with high efficiency |

| With good cooling effect | |

| Precise temperature control ,evenly blowed, lowest defect rate | |

| Blow moulds changeable in one blow moulding machine | |

| Fully-automatic | With preform-autoloaded machine |

| Computer with touchscreen | |

| Directly link to filling machine automatically | |

| Reliable quality | Imported spare parts such as Mitsubishi Plc,Festo cylinder |

| Strong steel construction | |

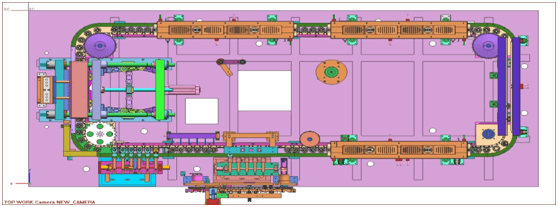

| Assembling according CAD design | |

| Aftersale service | Customer inspection before delivery |

| Machine delivered with necessary spare parts | |

| Technical engineer starting machine in buy’s country | |

| Quality garantee for one year | |

| Energy saving |

| LK-6000 Specifications | |||

| Model | Unit | LK-6000 | |

| Clamping System | Number of cavity | cavities | 6 |

| clamping unit | KG | 65000 | |

| mold stroke | mm | 90 | |

| stretch stroke | mm | 250 | |

| Bottom stroke | mm | 30 | |

| Cavity pitch | mm | 114.3 | |

| heating pitch | mm | 114.3 | |

| Number of holder | PCS | 114 | |

| Container | Max.container volume | ltr | 2 |

| Max. neck diameter | mm | 38 | |

| Max.prefrom height | mm | 100 | |

| Max.container diameter | mm | 65 | |

| Max.container height | mm | 250 | |

| ※theoretical output | B.P.H | 5500 | |

| Electrical System | heating oven | UNITS | 8*7 |

| box*channel | |||

| Number of lamp | pcs | 56 | |

| heating power | KW | 67.2 | |

| installed power | KW | 75 | |

| voltage | Voltage | 220v/380V/3 phase | |

Air System | operating pressure | kg/cm2 | 7 |

| blowing pressure | Mpa | 3.0 | |

| high pressure air consuming | L/min | 4800 | |

| power | KW | 55 | |

Chiller System | temperature | °C | 10-15 |

| pressure | Mpa | 0.4 | |

| flow rate | L/min | 80 | |

| heating power | HP | 8*7 | |

| Machine | machine dimension | M | 4.8*2.2*1.8 |

| machine weight | KG | 5500 | |

| Components | Brand,Origin |

| PLC controller | Delta, Taiwan |

| Touch screen | Wenview, Taiwan |

| Cylinder | SMC, Japan |

| Filter | TPC, Korea |

| Magnet valve | TPC, Korea |

| Photoelectric switch | OMRON,Japan |

| Contactor | Schneider,France |

| Proximity switch | SICK ,German |

| Sensor | OMRON,Japan |

| Switch power | MEANWELL,Taiwan |

| Frequency converter | Mitsubishi,Japan |

| Main Servo motor | Mitsubishi 1.5kw,JAPAN |

| Feeding Servo Motor | Mitsubishi 0.4kw,JAPAN |

| oil valve | Li Shile |

| Clamping | Hydraulic clamping |

| Seal | Pipe fixed |