- Mail Us: info@links-machine.com

- Call now: +86 158 5164 6970

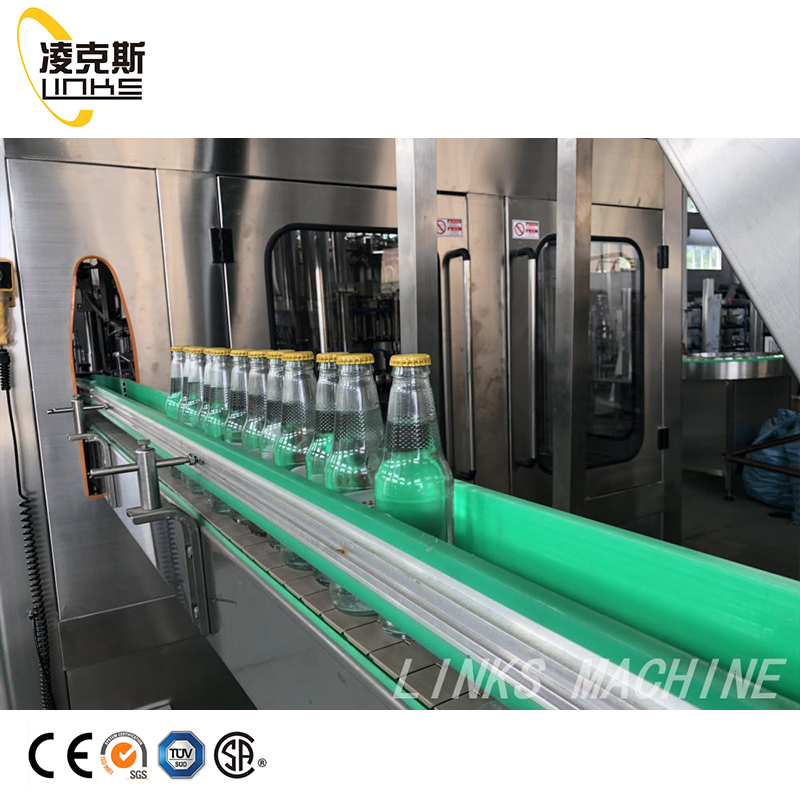

Beer Filling Machine adopts advanced “Secondary Vacuum and High Pressure Bubble Injection” technology to decrease oxygen content and improve the taste of beer; with precise pressure control and automatic defective bottle detection function, final product of Beer Filling Machine realizes perfect quality at all times.

Automatic Beer Filling Machine

1). Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2). Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

3). The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4). High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5). Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6). Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan's Mitsubishi, France Schneider, Siemens.

| Model No. | BXGF14-12-4 | BXGF18-18-6 | BXGF24-24-8 | BXGF32-32-8 | BXGF40-40-10 |

| Rinsing head no. | 14 | 18 | 24 | 32 | 40 |

| Filling head no. | 12 | 18 | 24 | 32 | 40 |

| Capping head no. | 4 | 6 | 8 | 8 | 10 |

| Production Capacity(bottle/hour) | 1000-1500 | 2500-4500 | 4500-6000 | 6000-8000 | 8000-9000 |

| Suitable bottle height(mm) | H=170-320,D=50-100(330-1500ml) | ||||

| Total Power(kw) | 1.5+0.37 | 2.2+0.37 | 3+0.45+0.25 | 5.5 | 7.5 |

| Overall dimension(L*W*H)(mm) | 2100*1680*2650 | 2500*1760*2650 | 3100*2100*2650 | 3800*2800*2650 | 4000*3300*3400 |

| Weight(kg) | 2600 | 3500 | 4650 | 6800 | 8500 |

| No. | Name of parts | Producing area |

| 1 | Programmed controller | MitsubishiJapan |

| 2 | Low-pressure breaker | Siemens Germany |

| 3 | AC electromagnetic contractor | Siemens Germany |

| 4 | AC electromagnetic contractor | Siemens Germany |

| 5 | Heat-break device | Siemens Germany |

| 6 | Multi-continuous electrical device | Siemens Germany |

| 7 | Middle-continuous electrical device | Omron Japan |

| 8 | Inducing on-off | AUTONICS USA |