©2019-2020 Zhangjiagang Links Machinery Co.,Ltd. All rights reserved.Site Map Privacy Policy

- Mail Us: info@links-machine.com

- Call now: +86 158 5164 6970

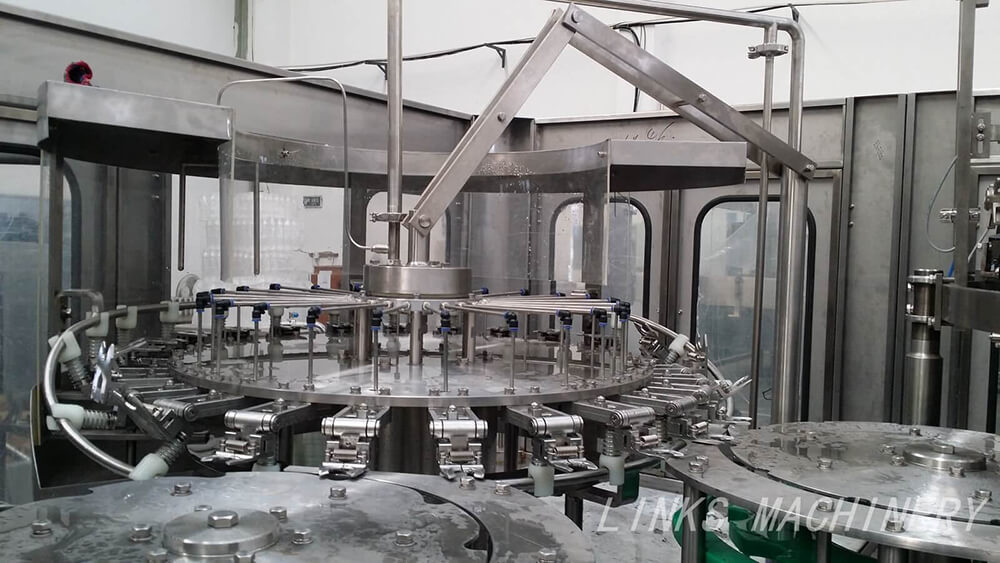

The machine is mainly used for filling carbonated drink. It combines rinsing and filling and capping as one automatic body suitable for PET or other plastic bottles. The iso-pressure (iso-barometric) filling technology is adopted enabling it to fill more efficiently and more stably with more output than the machine of the same level from others.

| Model No. | DXGF14-12-5 | DXGF16-16-5 | DXGF18-18-6 | DXGF24-24-6/8 | DXGF32-32-10 |

| Rinsing head | 14 | 16 | 18 | 24 | 32 |

| Filling head | 12 | 16 | 18 | 24 | 32 |

| Capping head | 5 | 5 | 6 | 8 | 10 |

| Power of main motor | 3kw | 3kw | 3kw | 4kw | 4.8kw |

| Total weight | 2.8T | 3.2T | 3.6T | 4.5T | 4.8T |

| Capacity | 2000-3000 | 3000-5000 | 6000-8000 | 8000-12000 | 12000-15000 |

| Bottle Diameter | 50-80MM | 50-80MM | 50-80MM | 50-80MM | 50-80MM |

| Bottle Height | 160-320MM | 160-320MM | 160-320MM | 160-320MM | 160-320MM |

| Method of changing speed | Frequency conversion | Frequency conversion | Frequency conversion | Frequency conversion | Frequency conversion |

| Power of unscramble motor | 0.37KW | 0.37KW | 0.37KW | 0.37KW | 0.37KW |

| Supply pressure of rinsing water | =0.06Mpa=0.2Mpa | =0.06Mpa=0.2Mpa | =0.06Mpa=0.2Mpa | =0.06Mpa=0.2Mpa | =0.06Mpa=0.2Mpa |

| No. | Name of parts | Producing area |

| 1 | Programmed controller | MitsubishiJapan |

| 2 | Low-pressure breaker | Siemens Germany |

| 3 | AC electromagnetic contractor | Siemens Germany |

| 4 | AC electromagnetic contractor | Siemens Germany |

| 5 | Heat-break device | Siemens Germany |

| 6 | Multi-continuous electrical device | Siemens Germany |

| 7 | Middle-continuous electrical device | Omron Japan |

| 8 | Inducing on-off | AUTONICS USA |