©2019-2020 Zhangjiagang Links Machinery Co.,Ltd. All rights reserved.Site Map Privacy Policy

- Mail Us: info@links-machine.com

- Call now: +86 158 5164 6970

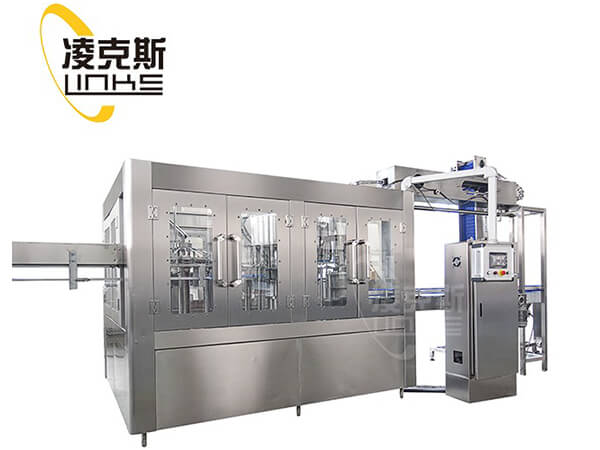

The three-in-one filling machine integrates cleaning, filling and sealing, and is suitable for hot filling production of various juices and tea beverages. The filling machine adopts microcomputer control system and pneumatic control system, which has reliable performance, simple operation and simple maintenance. The whole process of bottle cleaning, filling and capping is carried out in a closed state to realize aseptic filling . In the process of daily use, equipment maintenance is essential, now tell you how to carry out the daily maintenance of the three-in-one filling machine.

1. Keep the pipes of the three-in-one filling machine clean. All pipes, especially those in direct or indirect contact with materials, should be kept clean, washed once a week, and disinfected every time.

2. Make sure the three-in-one filling machine is clean, the storage tank should be scrubbed and disinfected to ensure that there is no dirt and bacteria in the parts that come into contact with the material.

3. In order to ensure the biological stability of bottled beverages during the production process, the sterilization time and temperature must be controlled to ensure the effect, avoid excessive sterilization time or high temperature to reduce beverage oxidation, and should be cooled as soon as possible after sterilization, so that the temperature does not exceed 35°C.

Low temperature filling is a low requirement for beverage filling, usually beverages are not easy to produce product foam in low temperature environment, which is conducive to filling, before each filling machine work, please use 0~1 ℃ water to lower the filling machine tank and The temperature of the conveying pipeline, when the filling temperature exceeds 4 °C, the temperature should be lowered first, and then the filling operation should be carried out.

4. The three-in-one filling machine uses a heat preservation tank for constant temperature filling at a certain temperature, and keeps the material at a constant temperature for a specified time, so as to prevent the liquid filling machine from working unstable due to excessive temperature changes.