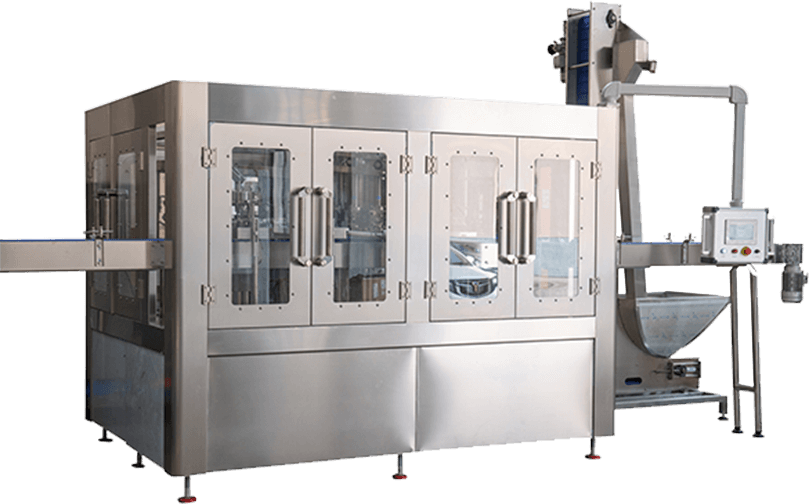

After filling, the bottle through transmission star wheel into the capping machine, the rubber MATS bottle neck, jointly with the gland closed bottleneck guard to keep the bottle upright and prevent in capping machine spindle rotation pressure LIDS to lead the revolution and rotation, implemented under the action of a CAM to finish the capping whole process.

The cap sealing head adopts the device of elastic constant torque. When the pressure head takes off the cover through the cap separating plate, the cap covers the cap and straightens the cap, so as to ensure the cap is in the correct position in the lid stamping die and ensure the quality of the cover sealing.

Capping plate pressure cap through pin wheel and transfer the power, to ensure the movement synchronization with capping machine, bottle cap through cap into the cap plate, and then cap passing star wheel separate cap according to the location to pressure cap, take cover when the capping plate pressure capping machine into a line of three modesty, suction cover unit in polymer CAM for suction head at the top of the capping machine.