OTHER MACHINERY FROM LINKS MACHINERY

| |

| |

|

High Speed Automatic Bottle Shrink Wrapping Machine is specially designed for high speed packing requirement of bottled drinking water (pure water, beverage, juice, milk etc). When conveying the bottles, it can arrange and film wrap the bottles automatically, which save the time and improve the working efficiency.

The one-piece film wrapping machine is based on the heat shrinkage characteristics of the packaging film. It uses photoelectric switch sensors to detect online. The collected signals are controlled and processed by PLC (programmable controller) programs. The conveyor belt is used for continuous bottle feeding, bottle separation, and pressure The whole process is completed

by the mechanism of bottle, put the bottle, push the bottle with continuous push rod, single-piece film coating, film picking and packaging, heating channel contraction, cold air cooling and shaping, etc

Technical Parameter / Electric Brands

Model | LK-A800-30 |

Capacity: | 20-25 Package/min |

Packing form | 2*2, 2*3, 3×4、4×6 (or appointed packing spec) |

Applicable container shape | circular container、 PE bottle、container outer diameter:¢40~¢110,height :60~340mm circular or quadrate container. |

Total power charge | 55kw |

Machine size | L10050*W1500*H2100mm |

Operating air pressure | 0.6~0.8Mpa |

Thickness of shrink film | 0.03-0.15mm |

Conveyor height | according to fills Production line (Adjusting scope 200mm) |

Width of film roll | ≤600mm |

Diameter of film roll: | ≤450mm |

Maximum packaging size | 450*450*300MM |

Shrink Temperature | 130-220℃ |

Shrink time: | 0-6S |

Brand Parts

Number | Material name | Specification model | Brand |

1 | PLC | 6es7 288-1st60-0aa0 | Siemens |

2 | Bus connector | 6ES7972-0BA11-0XA 0 | Siemens |

3 | HMI | 6AV6648-0CE11-3AX0 |

Siemens |

4 | cable | Connection line between PLC and touch screen |

Siemens |

5 | air switch | A9F19340 3P 40A | Schneider |

6 | air switch | A9F19316 3P 16A | Schneider |

7 | air switch | OSMC32N1C10 | Schneider |

8 | air switch | A9F19210 2P 10A | Schneider |

9 | Power contactor | LC1D4010M7C | Schneider |

10 | Intermediat e relay | RXM2LB2BD+RX2E 1M2C | Schneider |

11 | DC power supply | 350W | Schneider |

12 | Frequency | 6SL3210-5BE17-5UV | Siemens |

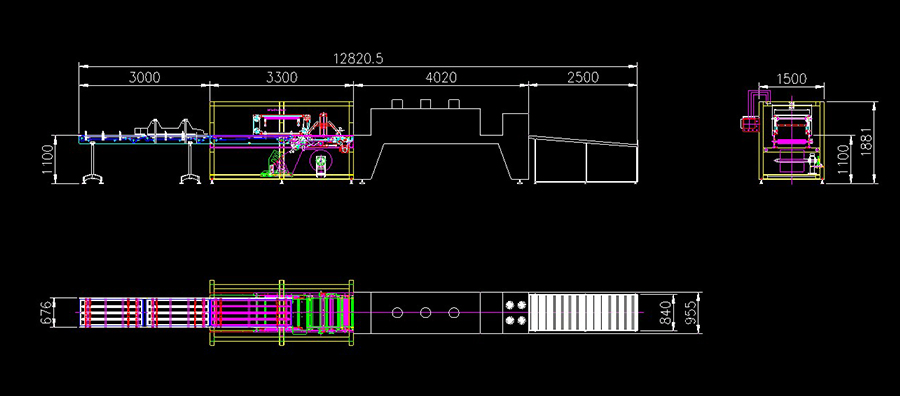

Layout

OTHER MACHINERY FROM LINKS MACHINERY

| |

| |

|

18 months for machinery parts; 12 months for electric parts.

We provide the 1 year easy broken spare parts for customer together with the machine delivery.

During the warranty time, we provide the free-charge spare parts.

Normally, our delivery time is 45-60days, it depends the types of machines.

We send our engineers to customer for installation and training, the time around 20-40days, it depends different kinds machines. Salary is 100USD/Day.

We are the original factory. We are more strict about our brand and machine quality.

We can provide the low cost of spare parts to our customer, and faster after-sales response.