OTHER MACHINERY FROM LINKS MACHINERY

| |

| |

|

1.Solo ONE independent main bearing system with concentric supports driving the up and down turnplates. No locking of supports & easy adjustment of turnplate heights avoid affecting the accuracy. 2.Separated heating units are easy for change-over. 3.The cage shaped roller frame avoids inaccuracy due to the fabrication error.

Technical Parameter / Electric Brands

No. | Item | Parameter data | |

Model | LK-R-9 | LK-R-15 | |

1 | Voltage | 380V/220V | 380V/220V |

2 | Frequency | 60Hz/50HZ | 60Hz/50HZ |

3 | Power | 8KW | 9.5KW |

4 | Available bottle dimension | Diameter:40-105mm, height=80-350MM | Diameter:40-105mm, height=80-350MM |

5 | Label specification | Length:125-325mm,Height:20-150mm | Length:125-325mm,Height:20-150mm |

6 | Gluing way | Roll painting(about 10mm, both label head and tail) | Roll painting(about 10mm, both label head and tail) |

7 | Capacity | 9000 bottles per hour (500ml bottle) | 15000 bottles per hour (500ml bottle) |

8 | Glue Consumption | l kg/ 100,000 bolttles (label height:50mm) | l kg/ 100,000 bolttles (label height:50mm) |

9 | Compressed Air Pressure | MIN5.0bar MAX8.0bar | MIN5.0bar MAX8.0bar |

10 | Consumption of Compressed Air | 0.2M³/minute | 0.2M³/minute |

11 | Total Weight | 2500Kg | 3000Kg |

12 | Overall dimension | L=3150,W=1770,H=1800 | L=3650,W=1970,H=1800 |

Brand List

No. | Name | Quantity | Brand |

1 | Touch screen | 1 | Schneider |

2 | Motion Controller | 1 | Schneider |

3 | Servo driver | 1 | Schneider |

4 | Servo motor | 1 | Schneider |

5 | PLC | 1 | Schneider |

6 | Analog Output Electronic Modules | 1 | Schneider |

7 | Encoder | 1 | Sick |

8 | Inverter | 2 | Schneider |

9 | Inverter | 1 | Schneider |

10 | Inverter | 1 | Schneider |

11 | Bottle sensor | 1 | Panasonic |

12 | Label sensor | 2 | Panasonic |

13 | Circuit breaker | 1 | Schneider |

14 | Circuit breaker | 5 | Schneider |

15 | Circuit breaker | 3 | Schneider |

16 | Contactor | 1 | Schneider |

17 | Contactor | 4 | Schneider |

18 | power | 1 | Schneider |

19 | Push-button | 1 | Schneider |

20 | Push-button | 1 | Schneider |

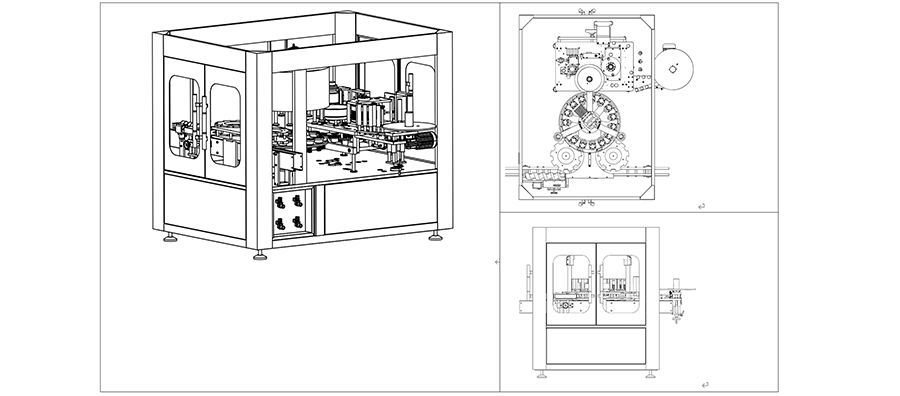

Layout as reference

OTHER MACHINERY FROM LINKS MACHINERY

| |

| |

|

18 months for machinery parts; 12 months for electric parts.

We provide the 1 year easy broken spare parts for customer together with the machine delivery.

During the warranty time, we provide the free-charge spare parts.

Normally, our delivery time is 45-60days, it depends the types of machines.

We send our engineers to customer for installation and training, the time around 20-40days, it depends different kinds machines. Salary is 100USD/Day.

We are the original factory. We are more strict about our brand and machine quality.

We can provide the low cost of spare parts to our customer, and faster after-sales response.