OTHER MACHINERY FROM LINKS MACHINERY

| |

| |

|

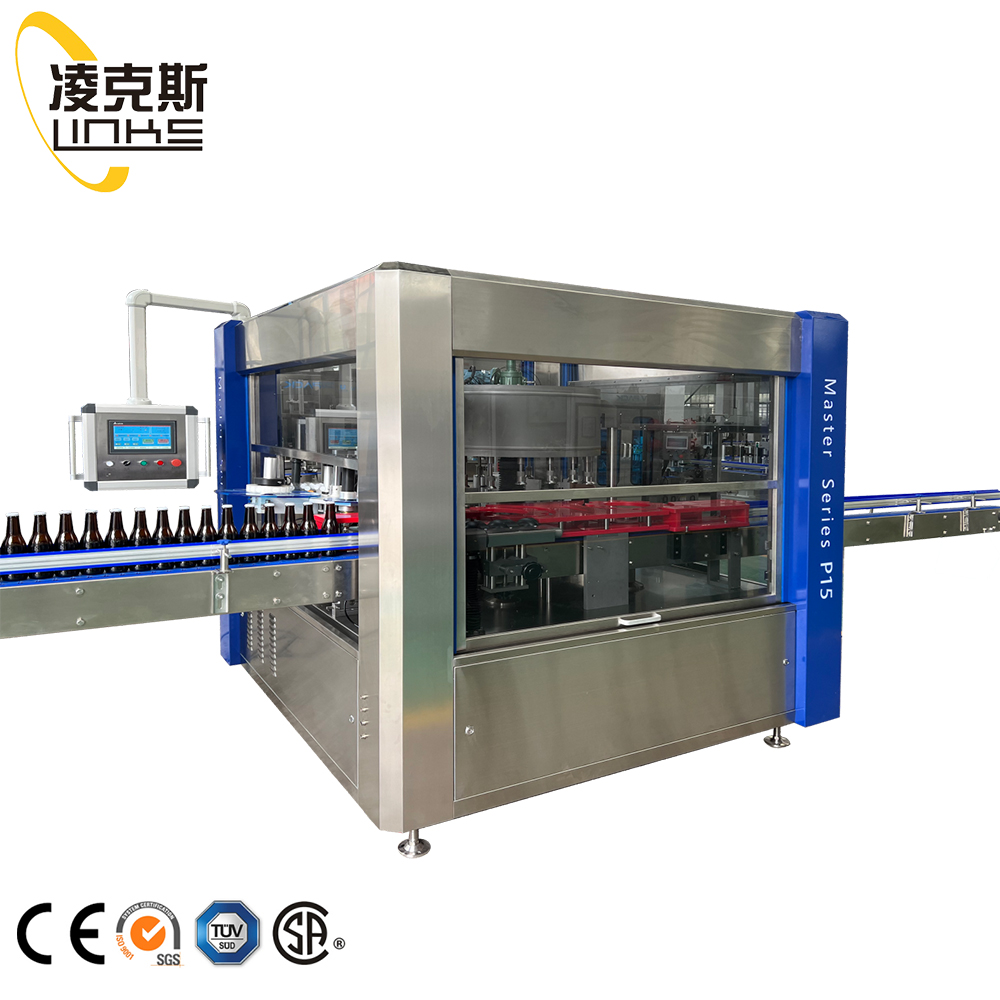

Each component is CNC processed for stable and quiet operation. Each has been inspected before being sent into the warehouse to ensure mechanical precision. - Waterproof container plates for round, square & nonstandard containers, fast changeover without requiring changing main components. - 8 container stations, with infeed and discharge conveyors on the same line. - Stable output rate of 27,000 BPH, infinitely variable speed adjustment, matching with filling machines and improving production output. - Safety doors: the machine stops automatically when the doors are open.

Technical Parameter / Electric Brands

No. | Item | Parameter data | |

Model | LK-R-9 | LK-R-15 | |

1 | Voltage | 380V/220V | 380V/220V |

2 | Frequency | 60Hz/50HZ | 60Hz/50HZ |

3 | Power | 8KW | 9.5KW |

4 | Available bottle dimension | Diameter:40-105mm, height=80-350MM | Diameter:40-105mm, height=80-350MM |

5 | Label specification | Length:125-325mm,Height:20-150mm | Length:125-325mm,Height:20-150mm |

6 | Gluing way | Roll painting(about 10mm, both label head and tail) | Roll painting(about 10mm, both label head and tail) |

7 | Capacity | 9000 bottles per hour (500ml bottle) | 15000 bottles per hour (500ml bottle) |

8 | Compressed Air Pressure | MIN5.0bar MAX8.0bar | MIN5.0bar MAX8.0bar |

9 | Consumption of Compressed Air | 0.2M³/minute | 0.2M³/minute |

10 | Total Weight | 2500Kg | 3000Kg |

11 | Overall dimension | L=3150,W=1770,H=1800 | L=3650,W=1970,H=1800 |

Brand List

Name 名称 | Brand 品牌 | Origin 产地 |

伺服电机 servomotor | Panasonic松下 | Japan日本 |

伺服控制器 Servo controller | Panasonic松下 | Japan日本 |

可编程控制器 PLC | Siemens西门子 | Germany德国 |

触摸屏 Touch screen | Siemens西门子 | Germany德国 |

变频器 Frequency converter | Schneider施耐德 | France法国 |

急停开关 Emergency stop switch | Schneider施耐德 | France法国 |

开关电源 Switching power supply | Mean Well明纬 | Taiwan台湾 |

接近开关 Proximity switch | Autonics奥托尼克斯 | South Korea韩国 |

空气开关 Air switch | Schneider施耐德 | France法国 |

报警灯 Alarm lamp | Schneider施耐德 | France法国 |

检测光电(照瓶)Bottle light sensor | SICK | Germany德国 |

检测光电(照标)Light tag sensor | SICK | Germany德国 |

升降电机 Lifting machine | ABB | Switzerland瑞士 |

主动力电机 Power motor | ABB | Switzerland瑞士 |

注:由于特种原因,电器可能会临时变更为其他同等品牌。 Note: Due to special reasons, appliances may be temporarily changed to other equivalent brands. | ||

Machine Details

Layout as reference

OTHER MACHINERY FROM LINKS MACHINERY

| |

| |

|

18 months for machinery parts; 12 months for electric parts.

We provide the 1 year easy broken spare parts for customer together with the machine delivery.

During the warranty time, we provide the free-charge spare parts.

Normally, our delivery time is 45-60days, it depends the types of machines.

We send our engineers to customer for installation and training, the time around 20-40days, it depends different kinds machines. Salary is 100USD/Day.

We are the original factory. We are more strict about our brand and machine quality.

We can provide the low cost of spare parts to our customer, and faster after-sales response.

See Our Latest Delivery Update → [Global Delivery of Beverage Filling Machines – August 2025]