©2019-2020 Zhangjiagang Links Machinery Co.,Ltd. All rights reserved.Site Map Privacy Policy

- Mail Us: info@links-machine.com

- Call now: +86 158 5164 6970

Semi-Automatic Bottle Shrink Wrapping Machine is specially designed for low speed packing requirement of bottled drinking water (pure water, beverage, juice, milk etc). When conveying the bottles, it can arrange and film wrap the bottles automatically, which save the time and improve the working efficiency.

Semi-auto Bottle Film Wrapping Packing Machine

The Features of Semi-Automatic Bottle Shrink Wrapping Machine:

1.Up and down magnetic switch prevent sealing mistakes, and protect the operators.

2.The input position is adjustable, base on the size of products packaged.

3.Schneider PLC, Schneider AC contractor, and intelligent temperature controller performs stable.

4.Large power conveyer motor, with stepless speed regulating, ensures smooth feeding.

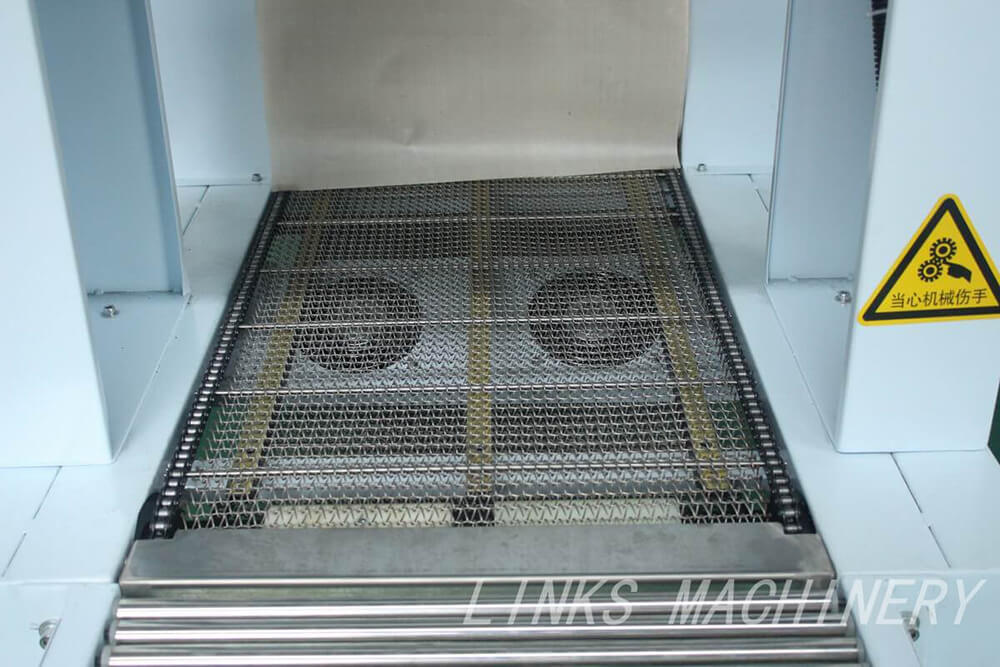

5.Up and down large power fan system ensures the excellent effect of shrinking in one time.

6.Super cooling system cools the packing and makes the figuration perfectly.

7.The size of tunnel can be customized as your request.

Semi-Automatic Bottle Shrink Wrapping Machine

It is PLC control, automatic work processing.

Constant temperature cutting blaes, which surface sprayed by Teflon, with the advantage of stable sealing.Touch screen is used to ensure easy operation.

Suit for different bottle size and packaging type without tray packing.

This type of shrink wrappig machine is your best choice for middle capacity, which is easy operation and maintance.

MBJ-B | Technical Parameters |

Speed | 2-5 bag/min |

Sealing time: | 0.5-1.5s 0-0.5s |

Conveyor loading: | 30kgs |

Film thickness: | 0.04-0.12mm |

Max. Packing dimension: | L W H 400*270*350MM |

Machine dimension: | 1020*830*1980mm 3900*900*1700mm |

Weight | 980kgs |