18000BPH Drinking Water 3-1 Washing-Filling-Capping Machine

- Mail Us: info@links-machine.com

- Call now: +86 158 5164 6970

This machine is mainly used for washing, filling, capping non-carbonated drinks such as pure/mineral water.

The machine shorten the contact time of the drinks material and outside, increasing the sanitation condition productivity and economy benefit.

Speed 18,000BPH

18000BPH Drinking Water 3-1 Washing-Filling-Capping Machine

Washing station ·Adopts SS304/316 Material. ·Using the reversal bottles washing type, bottle clamp stuck bottleneck, avoid the traditional bottle on rubber clip to block the bottle thread parts maybe caused by the pollution. ·Bottle clamp and lifting mechanism of sliding sleeve adopts Germany igus corrosion resistant bearing no need maintenance Adopt special design outsider bottle washing |  |

| Filling Station ·Adopts SS304/316 Material. ·All parts using CNC machining center equipment. Improve the machining accuracy at the same time, ensure good interchangeability of parts. ·All filling valve sealing materials using ozone resistance, corrosion-resistant sealing ring. All contact with the logistics part of health materials. ·By filling machine lifting device, can do liquid level height adjustable. |

Capping station ·Adopts SS304/316 Material. ·Uses the technology of Arol from Italy, most advance technology in the world, developed with the experience of asepsis filling machine ·Cap distributing chute is equipped with reverse cap stop and reverse cap pick-out mechanism. ·Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute. ·The capper is equipped with inlet bottle detection switch. Centrifugal way of cap arranging is adopted to reduce damage of caps. |  |

| Name of parts | Brand |

|---|---|

| Frequency converter (Inverter) | Siemens |

| PLC Control | Siemens |

| Touch screen | Siemens |

| Contactor | Siemens |

| Hot relay | Siemens |

| Air switch | Siemens |

| Approaching switch | Germany SICK |

| Photoelectric switch | Germany SICK |

| Pneumatic components | Air Tac |

| Motor | ABB |

| Pump | CNP |

| Model | XGF14-12-5 |

|---|---|

| Number of washing positions | 40 |

| Number of filling positions | 40 |

| Number of capping positions | 12 |

| Capacity at 500ml bottles / hour | 18000bph |

| Suitable bottle height (mm) | 160-340 |

| Suitable bottle diameter (mm) | ¢50-¢90 |

| Power of main motor (KW) | 6.0 |

| Water pressure (Mpa) | 0.25-0.3Mpa |

| Shape dimension | 4260MM*2130MM*2250MM |

| Weight | 6500kg |

| Filling temperature | Normal temperature |

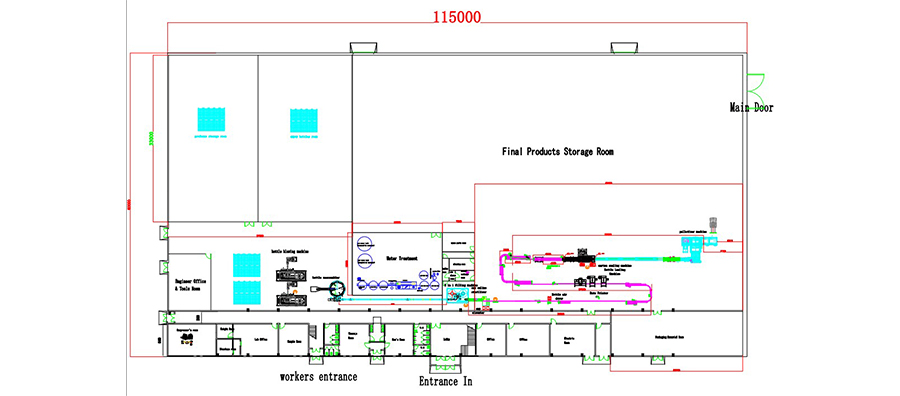

WATER PURIFICATION SYSTEM

| 1. Raw Water Tank—Water Pump—Silica Sand Filter | All parts adopts Stainless Steel 304 food grade(SS316L as option). |

| 2. Active Carbon Filter | Online type pressure auto self-protection device |

| 3. Na+ Ion Exchanger Filter | Online type electricity indicator |

| 4. Precision Filter (5um &1 um) | Online conductivity display |

| 5. Reverse Osmosis | Back washing system |

| 6. Ozone & UV sterilizer—Final Water Tank—Water Pump | Fault alarm display |

OTHER NECESSARY ACCESSORY MACHINES ON THE FILLING LINE

| PET Bottle Blow Molding MachineThis machine is use for kinds of different shape bottles(PET), widely use for different area, beverage, water, sparkling drinks, wine, beer…etc. Semi-auto bottle blower: need workers to operate on the machine, speed slow, small investment. Auto bottle blower: automatic operation, high level of automation, suitable for middle and high speed production plant. |

| Bottle Labeling MachineNormally has 3 type labels: ·Sleeve Label Shrink Machine: Most for PVC and PET material. ·Hot Melt Labeling Machine: For OPP material ·Adhesive Labeling Machine: For plastic/paper material |

| Bottle Packing MachineNormally has 3 types packing way: ·PE Film Shrink Wrapping Machine: use PE Film as material. ·Half Tray Shrink Packing Machine: use half tray and PE film as material. ·Caron Packing Machine: use carton as material |

18 months for machinery parts; 12 months for electric parts.

We provide the 1 year easy broken spare parts for customer together with the machine delivery.

During the warranty time, we provide the free-charge spare parts.

Normally, our delivery time is 45-60days, it depends the types of machines.

We send our engineers to customer for installation and training, the time around 20-40days, it depends different kinds machines. Salary is 100USD/Day.

We are the original factory. We are more strict about our brand and machine quality.

We can provide the low cost of spare parts to our customer, and faster after-sales response.