©2019-2020 Zhangjiagang Links Machinery Co.,Ltd. All rights reserved.Site Map Privacy Policy

- Mail Us: info@links-machine.com

- Call now: +86 158 5164 6970

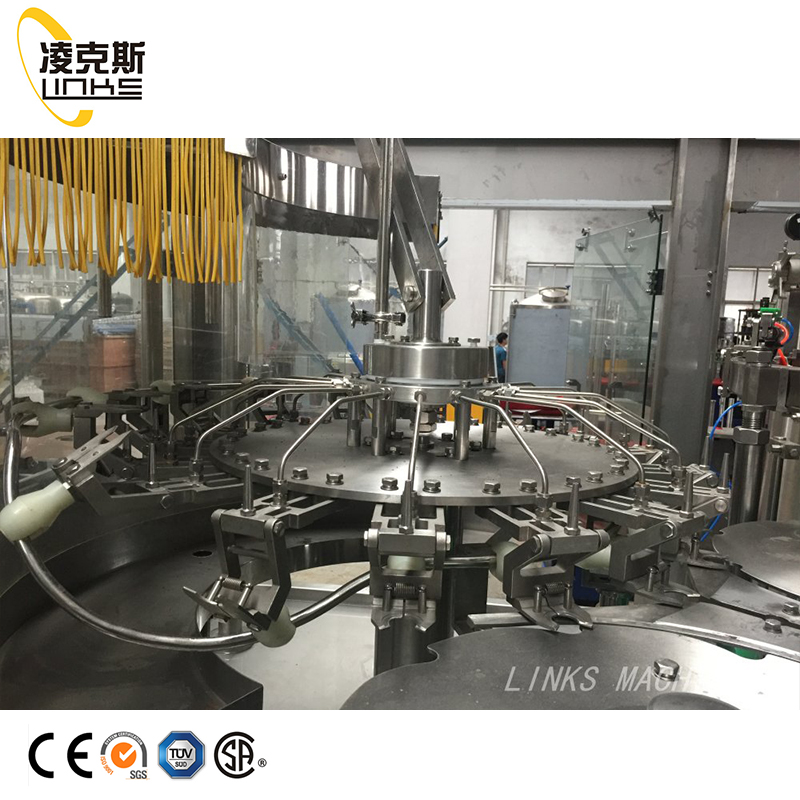

DXGF16-16-5 three-in-one machine for PET bottle integrates the function of rinsing, filling and capping together. Based on advanced technology overseas, and designed according to carbonated drinks filling processing demands.

Summary:

DXGF16-16-5 three-in-one machine for PET bottle integrates the function of rinsing, filling and capping together. Based on advanced technology overseas, and designed according to carbonated drinks filling processing demands.

Main features:

1. This machine has a compact structure, completed control system, easy to operate and highly automated.

2. By changing the star-wheel, screw bottle inlet and arc guide plate can realize to change the bottle shape.

3. The parts that direct contact with product are made of food grade stainless steel and no technology corner pockets and easy to clean.

4. By adopting high speed filling valve, the liquid level is precise and no waste. That guarantees the demand of filling technology.

5. The capping head adopts constant torque magnetic device to guarantee capping quality and impact cap.

6. The machine adopts high effective cap sorting system and completely self control and protective device.

7. The machine is equipped with perfect overload protective device that can keep the equipment and operator safely.

8. The control system has many functions, such as control producing speed, cap shortage detection, bottle block automatic stop and production counting etc.

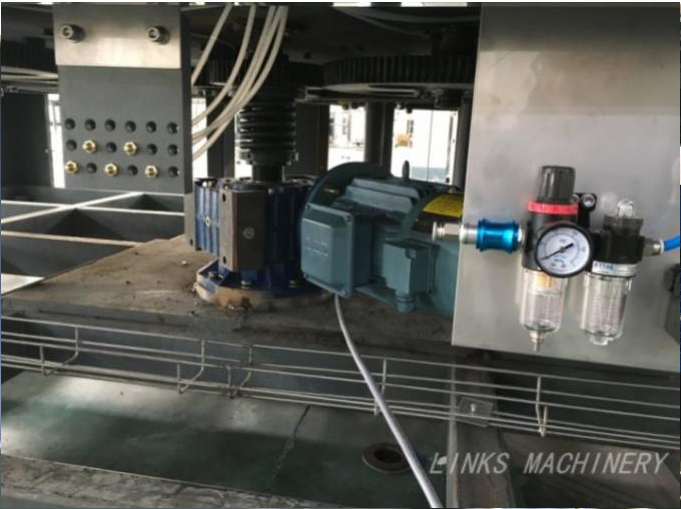

9. The electric components and pneumatic components are all introduced from world famous brand products.

10. The human-machine interface operation of the whole machine is realized by advanced pro-face.

Technical Date:

DXGF | 16-16-5 |

Number of washing positions | 16 |

Number of filling positions | 16 |

Number of capping positions | 5 |

Capacity at 500ml bottles / hour | 4000BPH |

Suitable bottle height (mm) | 160-340 |

Suitable bottle diameter (mm) | ¢50-¢90 |

Power of main motor (KW) | 2.5 |

Water pressure (Mpa) | 0.25-0.3Mpa |

Shape dimension | 2660MM*2230MM*2750MM |

Weight | 3600kg |

Filling temperature | 1-4degree |

Suitable bottle | PET bottle with screw cap |

Main components:

Serial No. | Name of Parts | Producing Area |

1 | Programmed controller | MITSHUBISH |

2 | On-off device | Taiwan |

3 | Low-pressure breaker | Siemens |

4 | Fuse | Japan |

5 | AC electromagnetic contractor | Siemens/OMRON |

6 | AC electromagnetic contractor | Siemens/OMRON |

7 | Heat-break device | Siemens/OMRON |

8 | Multi-continuous electrical device | Siemens/OMRON |

9 | Middle-continuous electrical device | Japan |

10 | Inducing on-off | AUTONICS |

11 | Speed adjusting | USA |

Machines superior characteristics

Main frame is equipment support frame, it is the premise of guarantee stable operation mechanism

Equipment main frame 120 x60x6 specifications high-strength carbon steel and welded together, each support distance less than 600mm, keep the machine stable and strong.

Washing station

Using the reversal bottles washing type, bottle clamp stuck bottleneck, avoid the traditional bottle on rubber clip to block the bottle thread parts may be caused by the pollution.All rushed bottle clamp strictly in accordance with the requirements of the company and precision production, ensure that each bottle of each parts can be achieved in the clip interchangeability, effectively reduce the customer after-sales maintenance and the company's inventory costs and fees.(Adopt special design outsider bottle washing.)

Bottle clamp and lifting mechanism of sliding sleeve adopts Germany igus corrosion resistant bearing no need maintenance.

Company proprietary technology, the design of large flow of small Angle bottle nozzle, effectively for the stand up after kowtowing internal effective spray, cleaning.

Filling Station

Filling valve structure design is reasonable, the high speed, high precision.All parts using CNC machining center equipment.Improve the machining accuracy at the same time, ensure good interchangeability of parts.All filling valve sealing materials using ozone resistance, corrosion-resistant sealing ring. All contact with the logistics part of health materials. By filling machine lifting device, can do liquid level height adjustable

Bottle clamp and lifting mechanism of sliding sleeve adopts Germany igus corrosion resistant bearing no need maintenance.

Capping station.

Capper is the machine with highest precision, influence very much with the stability and reliability of the filling monoblock. Our capper features as follows:

The equipment is designed with the support of experts from school of engineering and mechanical in Shanghai Jiao Tong University, and uses the technology of Arol from Italy, most advance technology in the world, developed with the experience of asepsis filling machine. For example, I) extruding wheel (main part to control the stability when sealing), uses the technology of Arol. Kinematical and kinetic design of the wheel by experts improves the stability and credibility of the equipment. II) Sealing faucet (main part to control the credibility of sealing), is improved by experts with the design of alnico. Besides the magnetic contortion variation device, there is variation dial which makes variation more easily. The benefit of this design is not only it can set the contortion, but also it makes contortion more precise and credible, and reduces inferior.

Cap distributing chute is equipped with reverse cap stop and reverse cap pick-out mechanism.

Cap distributing chute is equipped with a photocell switch to stop the capper when there is no cap inside the chute.

The capper is equipped with inlet bottle detection switch.

Centrifugal way of cap arranging is adopted to reduce damage of caps.

Electric Parts

All electrical components adopt international brand, reduce the failure rate control element. The equipment control cabinet is made of stainless steel waterproof electrical cabinets, configure a set of random operation screen at the same time, meet the demand of customer on-site monitoring and remote control.