©2019-2020 Zhangjiagang Links Machinery Co.,Ltd. All rights reserved.Site Map Privacy Policy

- Mail Us: info@links-machine.com

- Call now: +86 158 5164 6970

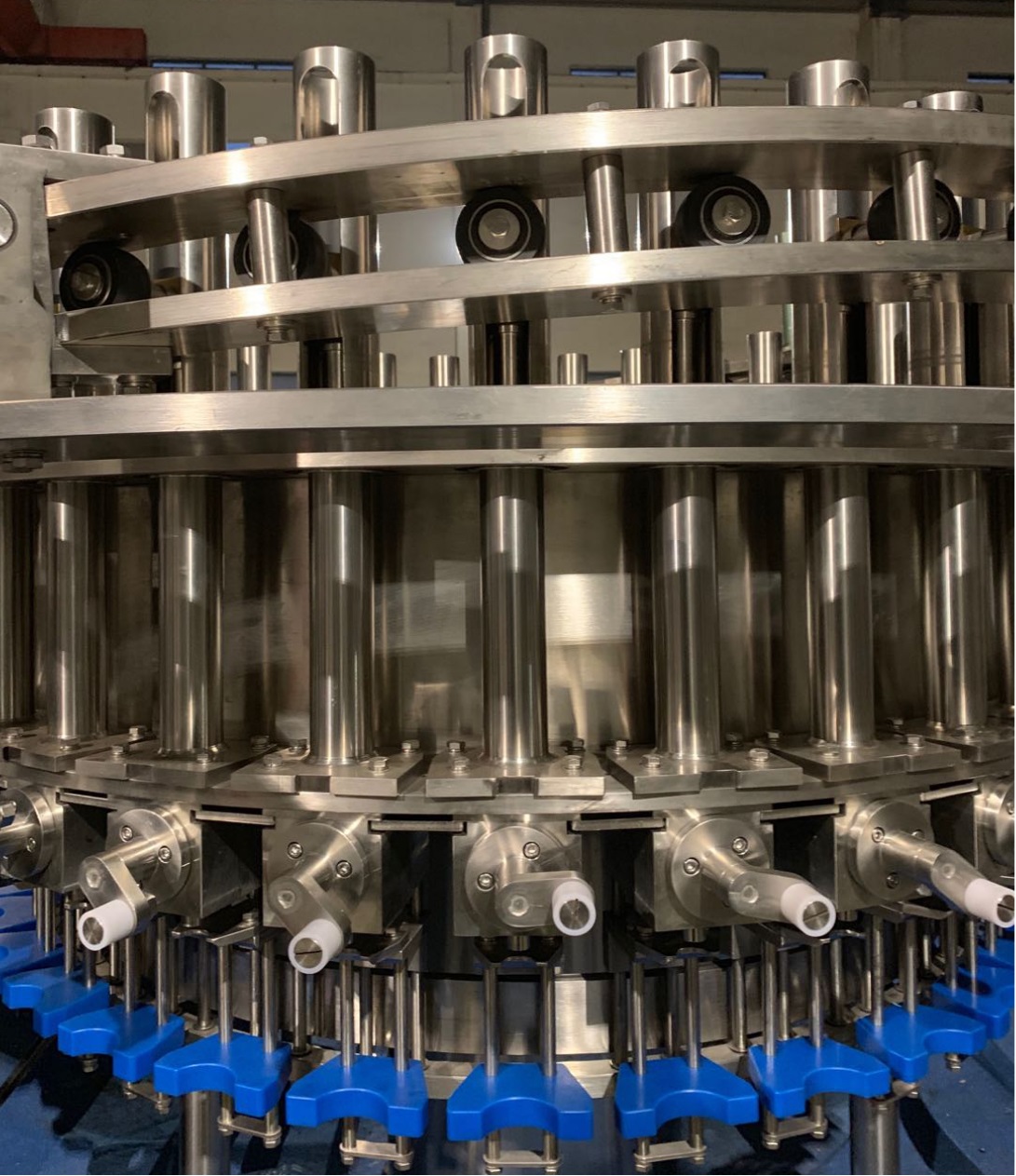

Using the reversal bottles washing type, bottle clamp stuck bottleneck, avoid the traditional bottle on rubber clip to block the bottle thread parts may be caused by the pollution. All rushed bottle clamp strictly in accordance with the requirements of the company and precision production, ensure that each bottle of each parts can be achieved in the clip interchangeability, effectively reduce the customer after-sales maintenance and the company's inventory costs and fees.(Adopt special design outsider bottle washing.) Bottle clamp and lifting mechanism of sliding sleeve adopts Germany igus corrosion resistant bearing no need maintenance.

Rinser

Using the reversal bottles washing type, bottle clamp stuck bottleneck, avoid the traditional bottle on rubber clip to block the bottle thread parts may be caused by the pollution. All rushed bottle clamp strictly in accordance with the requirements of the company and precision production, ensure that each bottle of each parts can be achieved in the clip interchangeability, effectively reduce the customer after-sales maintenance and the company's inventory costs and fees.(Adopt special design outsider bottle washing.)

Bottle clamp and lifting mechanism of sliding sleeve adopts Germany igus corrosion resistant bearing no need maintenance.

Piston Filling

When filling the bottle used for positioning card bottle hanging device, stable operation and reliable bottle filling valve on the hanging plate through the plunger type under the action of tour guide, then open valve mechanism in the cylinder under the action of open began to inject a certain material filling (non-contact) after reaching the schedule set level filling valve shut valve shutdown, and then through the steel star from a bottle filling particles outward remittance and transfer to the next working procedure - Pressure cap

Piston filling valve, suitable for filling various kinds of sauces (such as ketchup, hot pepper sauce jam puree with grain of rice wine by various water etc.), high concentration and viscous material containing pulp or particles, and smooth operation even pure liquid quantitative filling precision, suitable for cold hot filling piston and piston cylinder through cutting-edge science and technology, special processing, cooperate with precision, excellent durability The filling of hot pepper paste adopts the plunger method. The hot pepper paste is pumped into the quantitative cylinder through the plunger in the filling cylinder. When the set amount is reached, the filling valve changes the quantitative cylinder from the pumping channel to the filling channel by reversing.

The filling cylinder is equipped with a stirring device, through which the mixed materials of hot pepper paste in the cylinder can reach a uniform state to ensure that the materials entering the quantitative cylinder are uniform.

Capper

After filling, the bottle through transmission star wheel into the capping machine, the rubber MATS bottle neck, jointly with the gland closed bottleneck guard to keep the bottle upright and prevent in capping machine spindle rotation pressure LIDS to lead the revolution and rotation, implemented under the action of a CAM to finish the capping whole process.

The cap sealing head adopts the device of elastic constant torque. When the pressure head takes off the cover through the cap separating plate, the cap covers the cap and straightens the cap, so as to ensure the cap is in the correct position in the lid stamping die and ensure the quality of the cover sealing

Capping plate pressure cap through pin wheel and transfer the power, to ensure the movement synchronization with capping machine, bottle cap through cap into the cap plate, and then cap passing star wheel separate cap according to the location to pressure cap, take cover when the capping plate pressure capping machine into a line of three modesty, suction cover unit in polymer CAM for suction head at the top of the capping machine.